ROCKPORT, TX – Edison Golf, a company dedicated to revolutionizing wedge performance for everyday recreational golfers, is pleased to announce that Terry Koehler, Founder & Director of Innovation at Edison Golf, was a recent guest on The Off Course Golf Podcast hosted by Dan Edwards.

During the show, Koehler’s passion for the game is evident as he walks through a fascinating history of wedge design, bringing it to present day designs and the idea behind one sole style for all playing conditions. Dan and Terry dive into many topics including more mass higher on the club head and sole designs and grinds.

Topics discussed during the podcast include:

- Benefitting From More Mass Higher

- One Sole for All Conditions

- Benefits of Milling Patterns

- Risk Free Trial

- And so much more

Koehler, who also writes a popular weekly blog as The Wedge Guy on GolfWRX.com, has spent more than 40 years designing golf clubs. His work in wedges dates to 1990 with his patented sole design, which incorporated two distinct bounce angles in the sole of each wedge to deliver versatility for any lie and swing path. Shortly thereafter, he pioneered raising the CG (center of mass) of wedges with Reid Lockhart®, and his EIDOLON® wedges of the early 2000s were the first to introduce CNC-milled grooves in mainstream wedges. Koehler’s wedge design breakthroughs were further advanced with his progressive weighting technology in the SCOR™ wedges of 2011-2014 and the Ben Hogan® TK wedges of 2015-2017.

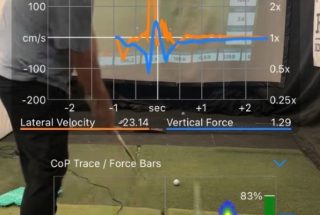

Edison Golf’s Edison 2.0 wedges represent a quantum leap in wedge design because they are the only wedges on the market specifically designed around a 30-year study of the way recreational golfers hit their wedges, as opposed to being designed for the exquisite skills of elite tour professionals. They have the most efficient distribution of clubhead mass in the category to deliver improved distance consistency, more forgiveness and enhanced spin.

Introduced in 2020, the original Edison Forged wedges significantly improved wedge performance by dramatically changing the way mass was distributed across the back of the clubhead. The Edison 2.0 line of wedges advance that performance superiority by positioning an additional 14-17 grams even higher in the clubhead, achieved by the creation of a multi-level back design that optimizes smash factor across the face. This repositioning also creates a fresh and distinctive visual appeal to the product.

In addition to enhanced weighting technologies, the Edison 2.0 wedges feature an improved version of the renowned and proven “Koehler Sole”. Patented by Koehler over 30 years ago, this unique sole design is the most versatile sole in the wedge category, as it combines both a high and low bounce into each wedge to handle different lies and different swing paths.

All Edison 2.0 wedges are backed by the Company’s 100% Risk Free Trial. The Edison craftsmen will custom build any Edison 2.0 wedge and ship it to you with shipping paid for by Edison. You can put it to the test on your course, hitting the variety of shots you face every round. If for any reason it’s not the best wedge you’ve ever played, Edison Golf will buy it back.

You can listen to the show at the Hackers Paradise website or via video at the THPGolf YouTube Channel

For more information about Edison 2.0 wedges, please visit EdisonWedges.com.

About Edison Golf Company

About Edison Golf Company

Edison Golf Company was formed in 2018 to provide a platform for development of the Edison Forged wedges and is establishing itself as golf’s premier custom wedge brand. Over the past 30 years, Chairman/Director of Innovation, Terry Koehler has raised the bar for wedge performance multiple times through his designs bearing the names Merit® Golf, Reid Lockhart®, EIDOLON®, SCOR™ and Ben Hogan®. He has repeatedly conducted robotic and live golfer testing of the top brands of ‘tour design’ wedges in his quest to improve golfer’s scoring range performance. Edison wedges were born from the scientific proof that poor distance control, insufficient spin and excessively high ball flight are built into the traditional ‘tour design’ that is reflected in nearly every wedge in the industry today. The company insists on the highest quality components and workmanship and all Edison wedges are custom-built to order for each customer from the Company’s assembly and shipping operations center in Rockport, Texas.

For Media Information, Contact:

Tracy Nackel, TEN Marketing & PR, 760-420-1602 or tnackel@gmail.com